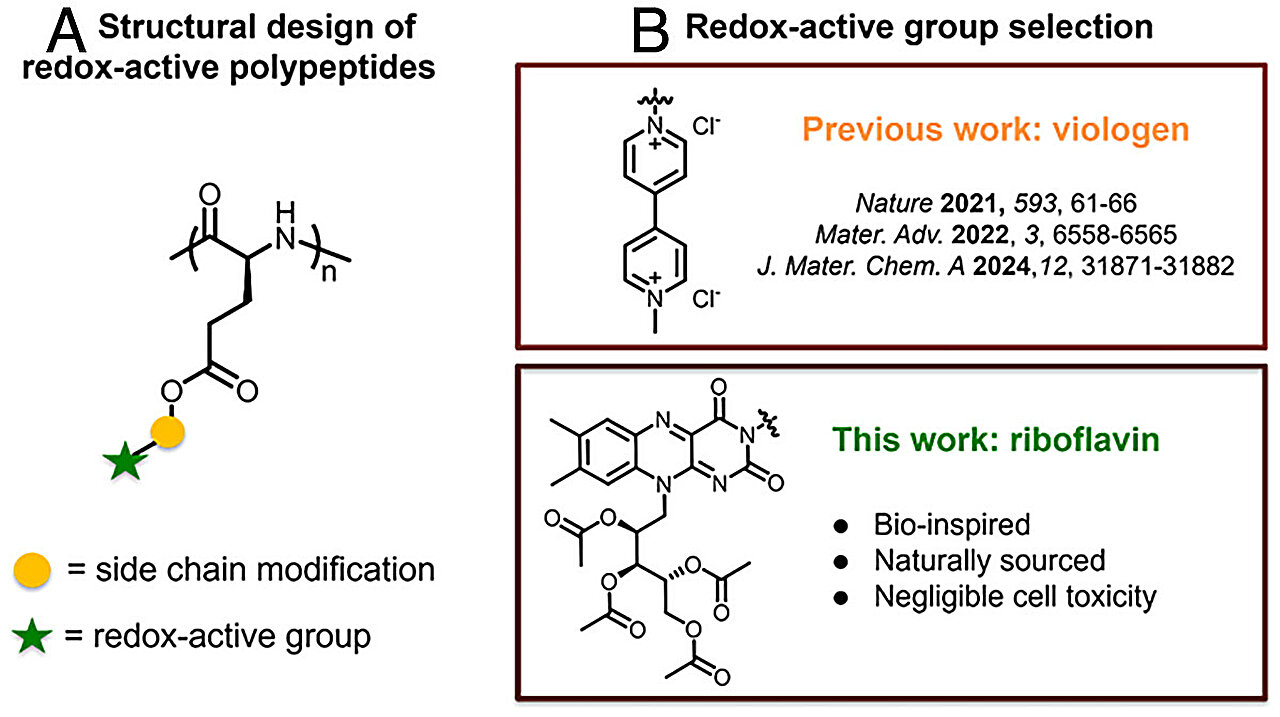

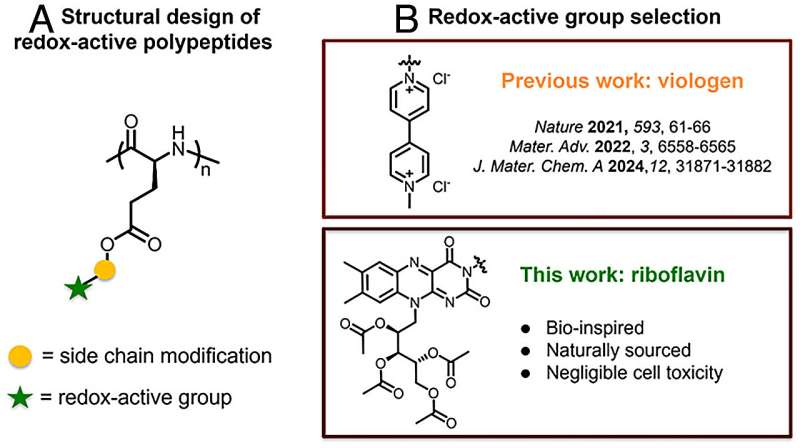

(A) Structural design of polypeptides that carry redox-active trailer groups. (B) Riboflavin was selected as a potential electrical alternative to vologous to improve the sustainability and biocompatibility of the resulting redoxactive polypeptide. Credit: Procedure of the National Academy of Sciences (2025). DOI: 10.1073/PNAS.2509325122

What if the next battery you buy has been made from the same types of ingredients in your body? This is the idea behind a groundbreaking battery material from natural, biodegradable components. It is so natural that it could even be consumed as food.

A team of researchers from the Texas A&M University, including Distinguished Professor of Chemistry Dr. Karen Wooley and professor of chemical engineering Dr. Jodie Lutkenhaus, has developed a biodegradable battery with natural polymers. The results are published in the Procedure of the National Academy of Sciences.

The Wooley's research group at the College of Arts and Sciences has changed in the past 15 years towards natural substances for the construction of sustainable and degradable plastic materials. Lutkenhaus, Associate Dean for Research at College of Engineering, has used organic materials to design a better battery. She suggested a collaboration to the combination of Wooleys' combination of Wooleys, naturally obtained with her battery expertise.

“We were interested in safer, more flexible battery materials for a long time,” said Lutkenhaus. “When Dr. Wooley's laboratory began to develop these naturally standing polymers, the door opened it for something completely new – a battery that cuts off well and also disappears safely if it is no longer needed.”

A battery of vitamin B2 and amino acids

The new material consists of two important ingredients contained in nature: riboflavin, also known as vitamin B2, and L glutamic acid, an amino acid that helps to build proteins in the body.

“These components were identified by a talented doctoral student, Dr. Shih-Guo Li, who began his dissertation research five years ago to improve the content of biologically renewable building blocks for the battery for organic polymer batteries,” said Wooley. “He then developed synthetic methods to connect the molecular building blocks into chain -like structures, which are called polypeptides.”

What makes this material special is that it is redoxactive, which means that it can win and lose electrons. In this way, the batteries saved and released energy. In this case, the riboflavin processes the energy, while the polypeptide structure offers and the material collapses naturally.

In contrast to conventional lithium-ion batteries that rely on metals and petrochemicals, this new material is derived completely from renewable biological sources. It was designed in such a way that it is deteriorating if it is exposed to water or enzymes, which makes it a promising solution to reduce battery waste, especially in cases where batteries are not properly recycled.

“Although there are significant efforts to recycle batteries, in cases where batteries are not actively collected and processed into recycling, you should be able to naturally achieve a breakdown and publish non -toxic degradation products,” said Wooley.

Safer for the environment and living cells

In laboratory tests, the material showed its suitability as an anode, the part of a battery that stores electrons. It was also shown that the material is also non -toxic to fibroblast cells, a type of cell found in the connective tissue.

“At this point we only confirmed that our materials are cytocompatible, which means that they are not harmful to the cells,” said Wooley. “This can play a role if the materials should be used in implantable or portable devices.”

Lutkenhaus said that the performance results were particularly promising given the natural origins of the material.

“We were enthusiastic to see that electrochemical behavior with synthetic non -sustainable polymer materials corresponds,” she said. “It shows that you do not have to sacrifice performance to achieve sustainability.”

On a circular future for the battery design

The researchers say that this type of design – with the end – is the key to building up a more sustainable future. Instead of creating materials that take forever and become waste, design them as part of a circular economy, in which materials are reused, recycled or securely returned to nature.

“I like to look at every synthetic material that my laboratory creates as a point on its journey towards the function and purpose,” said Wooley, “with the ability to carry out physical and chemical transformations that enable the reuse of molecular components in several other directions.

“In this case, the batteries could be edible to provide a different type of energy supply.”

The team is currently focusing on improving the performance of the material and finding ways to make it more affordable. The chemical process for the production of the material is currently too expensive for commercial use.

“We have to improve the performance and then develop processes that would be profitable,” said Wooley. “That could require 5-10 years.”

The excitement of interdisciplinary cooperation

One of the most exciting parts of the project, according to the researchers, was the collaboration in Texas A&M Colleges.

“As a chemist, the most exciting moment was when Professor Lutkenhaus's laboratory showed that our materials could be made into working battery systems,” said Wooley. “It was a confirmation that the strategy promises to advance.”

Lutkenhaus added: “It was a large milestone that was to be validated and gave us a clear direction for future development.”

Further information:

Shih-Guo Li et al., A bioinspired and degradable Riboflavin-containing polypeptide as a sustainable material for energy storage, Procedure of the National Academy of Sciences (2025). DOI: 10.1073/PNAS.2509325122

Provided by the Texas A & M University

Quote: Battery made of natural materials could replace conventional lithium-ion batteries (2025, September 24)

This document is subject to copyright. Apart from a fair handling of the purpose of the private study or research, no part may be reproduced without a written approval. The content is only provided for information purposes.